Peripheral Equipment for Hydraulic Die-casting Machines

< Page 1

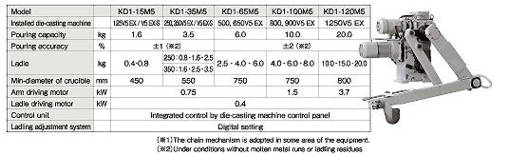

| Automatic Ladles KD1-M5 Series |

|

- With a linkage and full-bearing structure adapted to the driving unit, the automatic ladle can be operated smoothly with a minimum secular change. (*1)

- A dedicated inverter-driven AC motor and a link arm mechanism ensure smooth operation.

- Ball bearings are used.

- A link mechanism is used for part of the ladle drive system, ensuring minimal change of pouring volume with time.

- The arm driving motor is equipped with a brake for increased stopping accuracy.

- Pre-tilting, and quick return of the ladle can be made by a microprocessor control. realizing high-cycle operation.

- Pouring volume can be easily adjusted by remote control.

- Changeover between acceleration and deceleration is smooth, and operation is shock-free even at high-speed

- High-low-high three-step pouring speed control. The use of a sleeve with a rectangular opening realizes hopper-less pouring.

|

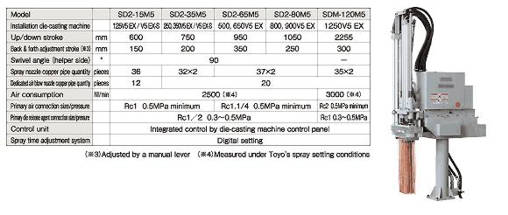

| Automatic Spray Units SD2-M5 Series |

|

- The spray control devices are integrated in a dedicated valve box to facilitate maintenance and adjustment.

- Can be installed on a fixed die plate. Microprocessor control makes operation simple. An early-starting function contributes to high-cycle operation.

- Spraying patterns can be chosen by mode setting.

- Nozzle cassettes can be changed quickly for each job.

- Easy-to-use, dedicated air blower is provided.

- The nozzle unit automatically swings 90 degrees to prevent the nozzle from hitting the core cylinder.

- The up/down cylinder is automatically locked at the upper limit.

- A dedicated valve box facilitates replacement of units.

- The adjustment valves are collected in a single panel to facilitate adjustments.

|

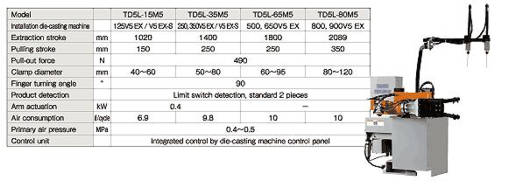

| Automatic Extractors TD5L-M5 Series |

|

- Smooth and high cycle operation by adoption of a dedicated inverter motor for driving arm.

- TD5L-M5 can be mounted on the die-casting machine, and it automates the extraction work.

- A dedicated inverter-driven AC motor and a link arm mechanism ensure smooth operation.

- The arm driving motor is equipped with a brake for better stopping performance.

- The main bearings are ball bearings.

- The moving arm has no electrical components, thus minimizing trouble and facilitating maintenance work.

- A microprocessor-controlled early-starting function realizes high-cycle casting.

- The unique link mechanism permits the ideal extraction motion followed by 90-degree swinging.

- The extractor can be installed directly on the die casting machine, conserving floor space.

- A new chucking mechanism does not need tip diameter size adjustment.

|

| Vacuum Unit VCSU-15 |

|

- This unit is controlled by a microprocessor of the die-casting machine. The wiring between this unit and the die-casting machine can be made easily using a metal conduit.

- An air purging function blows out aluminum burrs in the piping.

- An alarm signal is issued when the pressure inside the tank rises beyond 20 KPa.

|

| Automatic Dilutor AD-35 |

|

- Easy automatic dilution operation.

- The dilutant is automatically replenished when the level in the dilutant tank falls.

- Easy feed pressure adjustment.

- Spraying can be continued even while the raw liquid pail is being replaced.

- Uses a highly reliable air-driven pump.

|

|